What is cold bridging?

A cold bridge, or thermal bridge, is a part of a building that conducts higher levels of heat than materials surrounding it. This will likely cause an insulation break-through or ‘weak spot’, especially if insulation levels are being reduced overall. A cold bridge may also be caused by energy transfer through elements with higher thermal conductivity penetrating the insulation. Simply put, a cold bridge occurs when a warm structure meets a colder one.

Overall, the meaning of cold bridging is that the inside and outside of the building are bridged by materials which conduct heat. Therefore, additional heat loss can occur at these points, especially if the building is located within a cold environment.

Where do cold bridges commonly occur?

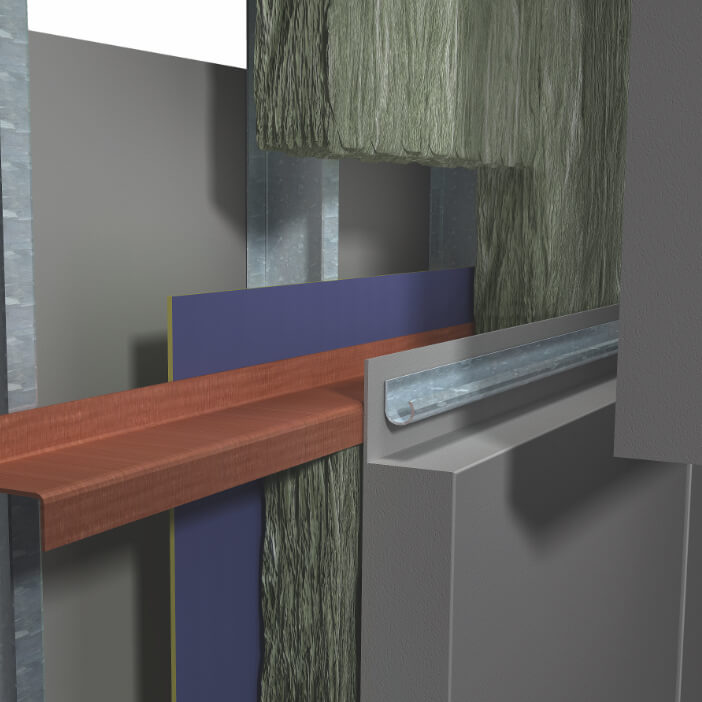

Armatherm™ FRR — Masonry Shelf Angle Cold Bridging Application

A serious cause of thermal bridges, masonry shelf angles and tie-backs, are a requirement of veneer walls. The heat loss through masonry shelf angles will negatively affect a building’s capability to meet energy codes. This is because veneer walls can result in thermal bridges, which reduce the R value of a wall up to 50%.

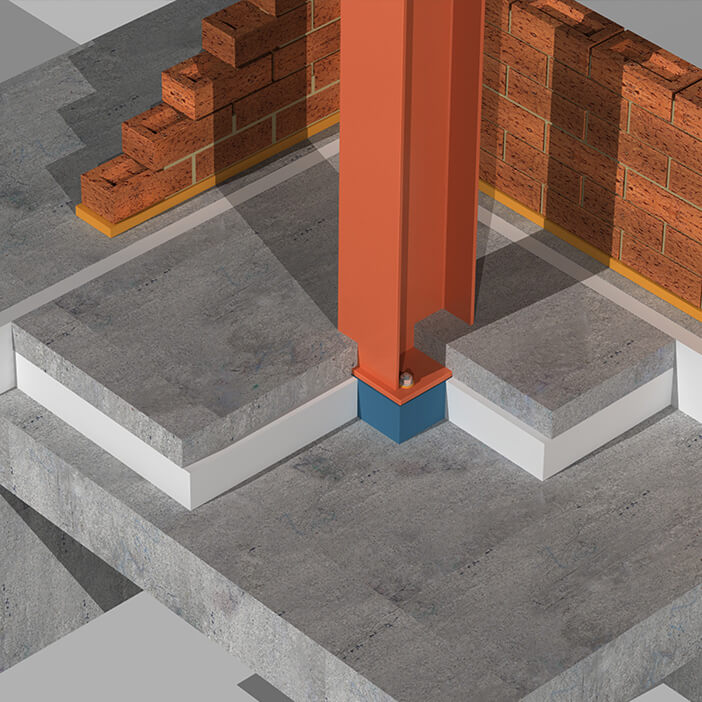

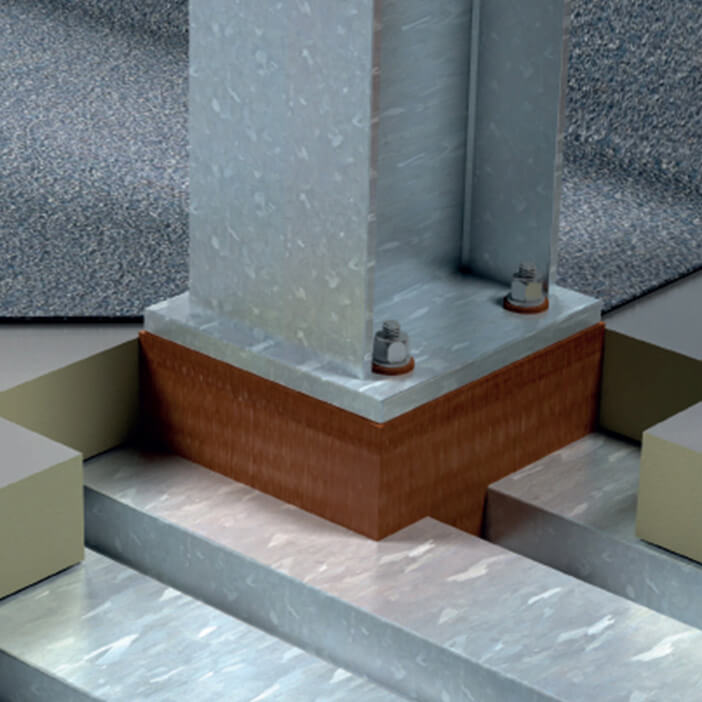

Armatherm™ 500 – Column Base Cold Bridging Application

At steel column bases, heat can be lost as these traditionally extend through buildings and floor slabs. This means that a thermal bridge is created through transmittance (heat loss) at the column’s base.

Armatherm™ 500 – Foundation Wall Cold Bridging Application

Foundation walls are essential to the thermal enveloping of buildings. They will likely feature an intersection on grade-to-wall connections. However, heat can escape through non-continuous insulation and cause a building to reduce its core temperature as a result.

Armatherm™ FRR – Balcony Canopy Cold Bridging Application

The structure of balconies and canopies means that they are typically attached to a building along its length. They tend to be made as an extension of the building floor slab, which means a continued connection into the building is made, along the length of the floor. As these connections are passed through the building envelope, the exterior insulation and air barrier is interrupted, creating a thermal bridge. Therefore, energy and heat is inevitably lost.

Armatherm™ FRR – Parapet Roof Penetration Cold Bridging Application

A parapet roof, an extension over the edge of the wall, adds further penetrations to the envelope and roof insulations, which causes non-continuous insulation. In fact, any additional roof features, such as solar panels, chimneys, air intakes will likely result in large energy and heat losses. This is because they break through insulation barriers. The R value of the exterior wall can be reduced by 60% with a parapet structure, due to the thermal bridges between the wall and roof.

Armatherm™ Z-Girt – Cladding Cold Bridging Application

Cladding can be a key mitigator of thermal bridging. The cladding attachments provided by Armatherm significantly improve wall assembly and thermal performance. For a combination of low thermal conductivity and high compressive strength transferring load and reducing heat loss, we’d recommend Armatherm FRR Z Girt, clip and thermal break shims.

Cold Bridging Insulation

Many stakeholders within the building industry are unaware of the negative implications of thermal bridging and are therefore unfamiliar with the structures in which it commonly occurs. Armatherm is one of the leading suppliers of thermal break materials for the construction industry, with a key goal of providing architects, engineers, and contractors with the insight and materials to effectively address cold bridging.

The aim with most buildings currently is to build energy efficiently and to protect the future of construction projects. Incorporating Armatherm reduces and eradicates the risk of cold bridges which bypass insulation to sap energy and cause unhealthy environments with the potential for mould and dampness. Thermal breaks offer long lasting and effective solutions to these problems. You can also be provided with advice and guidance from Armatherm’s expert team.

As the UK government has set the world’s most ambitious climate change targets into law, with emissions targeted to dramatically reduce by 2035, energy saving becomes increasingly necessary to achieve sustainable goals.

Therefore, it’s important to identify where improvements can be made, utilising energy saving advice and materials that will sustainably last the lifetime of the building and work towards reducing environmental impact. Armatherm is continuously improving the product range it offers, and is always developing new materials to meet the needs of energy efficient buildings. Incorporating thermal breaks can improve the efficiency of a building by as much as 70%. This results in lower operating costs and prevention against cold spots where condensation can occur, reducing the need for renovations further down the line.

What are the specific cold bridge solutions offered?

There are now many reliable products available to prevent cold bridging, Armatherm can help you navigate through the solutions to reduce heat loss, increase sustainability and minimalise costs:

Armatherm™ FRR

Armatherm FRR is suitable for supporting heavier loads as it is a strong and durable thermal break option. It also minimises conductive heat loss through the insulation layers. As a structural thermal break, it provides an innovative combination of low thermal conductivity and high compressive strength. Hundreds of structural steel framing connections have specified it as transferring load in moment and shear conditions. The product is made from reinforced, thermoset resin, this material is fire resistant and will reduce heat loss an additional 4% per bolt depending on the wall assembly construction. It’s perfect for façade thermal break applications and structural steel.

Armatherm™ Z Girt

The Armatherm Z Girt is strong enough to hold most insulation cladding additions, as a nonconductive cladding support system. It prevents excessive potential condensation and heat flow problems which could arise without the inclusion of a thermal break product. Tested through modelling results, we can see that incorporating an Armatherm Z girt within a cladding project results in several improvements within the thermal efficiency of the wall design. This dramatically then reduces the heat flow. With an innovative design, this means that the attachments can significantly improve the wall assembly’s thermal performance. A combination of Z-girt, clip and shims can deliver the lowest levels of thermal conductivity and high mechanical properties that transfer load while reducing heat loss.

Armatherm™ 500

Armatherm 500 is a high strength, polyurethane material, it is available in various different densities to support a wide range of building loads. Utilising Armatherm 500 thermal breaks significantly minimises energy consumption alongside potential condensation issues. The material is extremely strong and will reduce energy lost from the building envelope, in a variety of connections. It is made from a durable, thermoset polyurethane, and manufactured in a variety of densities to provide unrivaled energy saving properties to a number of projects. Armatherm™ 500 can transfer a wide range of structural loads.

How can you learn more about cold bridging?

We have a dedicated team who work hard to ensure you feel supported and informed. Contact us to learn more. Armatherm™’s RIBA approved seminar, “Improving Building Envelope Performance” gives architects an insight to gain a better understanding of the invaluable properties and savings thermal breaks can offer, as well as how to apply them effectively to prevent thermal bridging issues in your next project conforming to RIBA standards.

Need help?

Contact us today to find out more or request a quote.

UK

UK USA

USA Canada

Canada Australia

Australia New Zealand

New Zealand Germany

Germany UAE

UAE Ireland

Ireland Sweden

Sweden Denmark

Denmark Norway

Norway