Why choose Armatherm™

Same day delivery option

Approved to BS standards

Stock always on hand

BBA accredited

Code compliance

LEED benefits

OurAccreditations

ThermalBreak resources

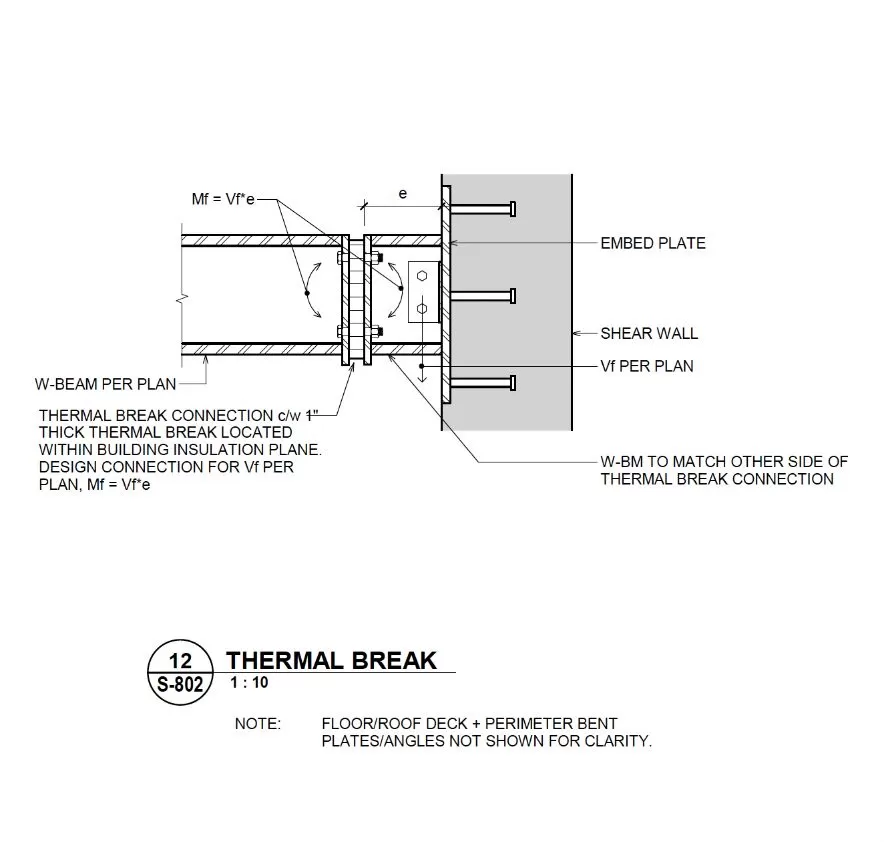

Take advantage of our valuable online resources on our website, including test reports, extensive literature libraries, design assistance and product profile videos to help you understand the importance of thermal break products, the key features of our products and the applications in which they can be used. If you require CAD drawings for your project, these can be accessed via the Armatherm™ website and downloaded to be easily incorporated into your project plans.

Our easy-to-follow online thermal breaks webinar is also accessible online, with the course providing an overview and introduction to thermal bridging, discussing how and why it occurs, as well as how it can be prevented. It showcases and compares the difference between building details with and without thermal break solutions to demonstrate the necessity of determining accurate values of thermal transmittance within a project.

Armatherm resources

Downloads

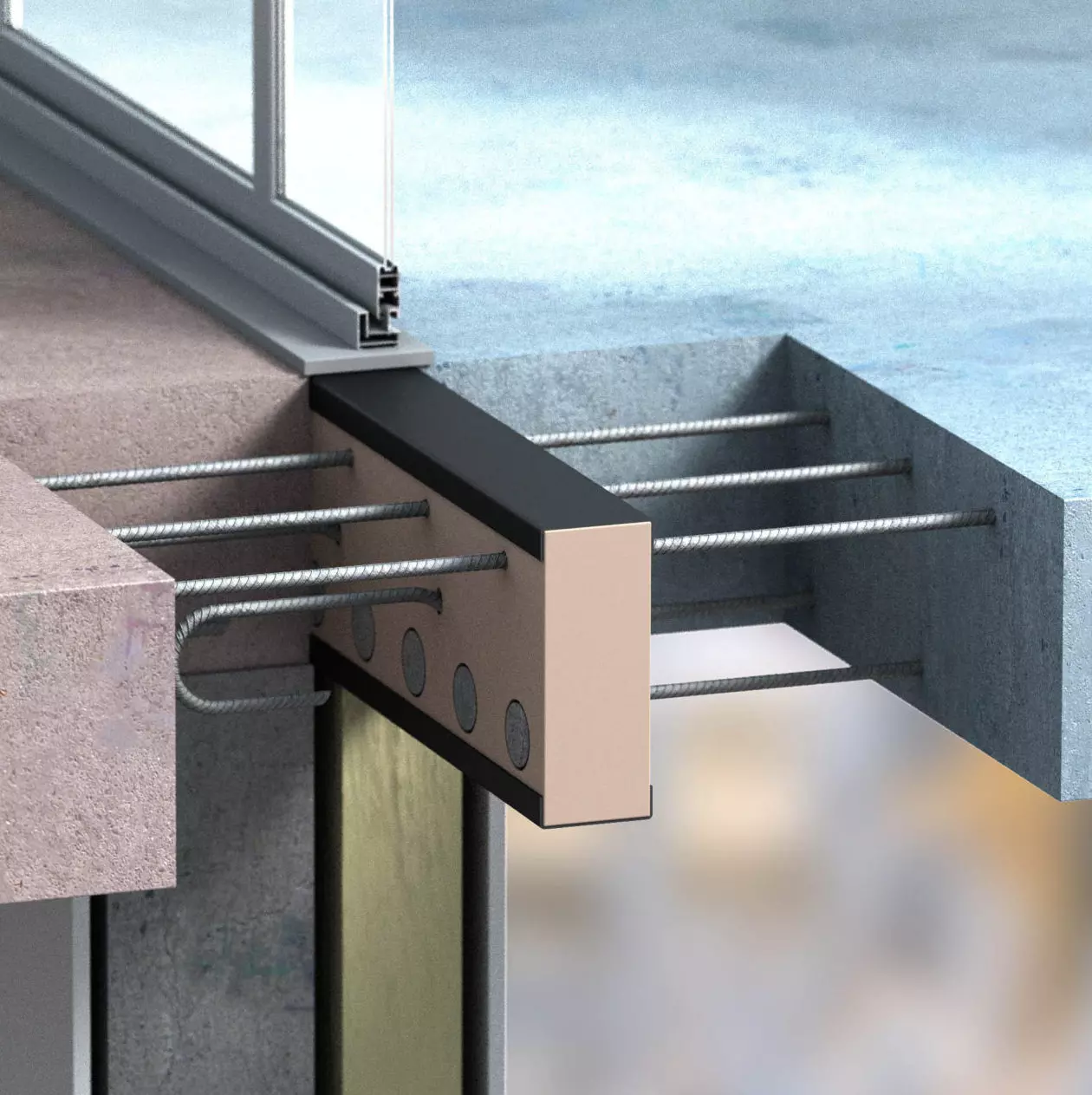

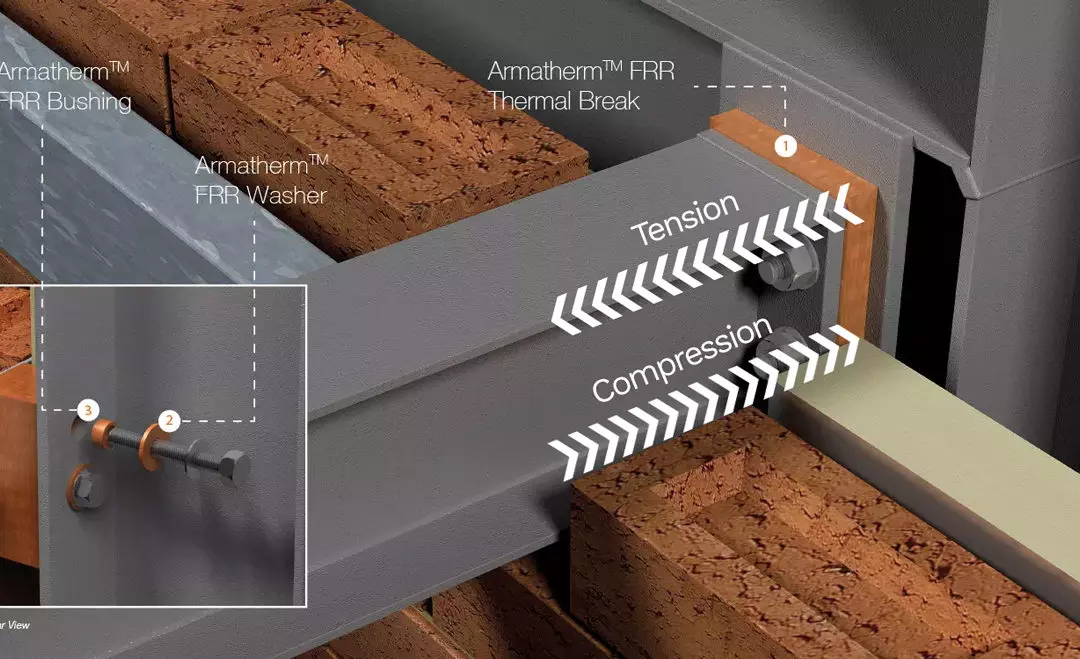

Armatherm™ FRR is a strong thermal break material solution. It is composed from reinforced thermoset resin, providing high compressive power and low thermal conductivity. Thermoset resin presents many benefits, namely limited combustibility and reduced creep under load, because of the elements which make it up. Due to this, it is most beneficial in structural thermal break connections, improving energy efficiency.

Damaging condensation, leading to mold and damp build-up, can be very dangerous. This condensation is most likely caused due to a reduced heat flow within a building’s thermal envelope, which highly reduces the structure’s energy consumption. Cold bridging, for example through concrete or steel framing, will significantly impact the energy performance stats of buildings. Incorporating these into your building structure will minimise the transfer of energy and temperatures, an essential process to move towards efficiency in structures and buildings worldwide.

Armatherm™’s FRR material is dynamic in its potential application uses. Its form options vary to suit your project, such as sheets, washers and bushings, all of which hold impressive specifications for thermal isolation. Armatherm™ FRR sheets satisfy U value and thickness specification requirements as they may be bonded together if your project requires. Standard thickness options are 12mm, 20mm, 25mm, 50mm, but it also comes in 3mm, 6mm, 10mm, 15mm – so whatever your requirment, the ideal material can be specified or created for you and your project.

It’s clear that it is very important for thermal break sheets to be incorporated within steel and concrete framing. Not only this, a thermal break should also be specified for the front side of the bol head, between the steel washer and face of the exterior steel. When thermal breaks are included at these points, it preserves a thermal bridge through the bolt. This would otherwise provide a path for heat to flow through the thermal break assembly and result in a loss of energy from inside the building. For reducing potential condensation as a result of these thermal bridges in the building envelopes, Armatherm™ washers and bushings are vital.

Armatherm™500 is one of our high strength thermal breaks. It consists of a ground-breaking polyurethane material which has been made in several densities, specifically to support a wide range of loading conditions within a building’s structure. The closed cell structure which it harbors does not absorb water and has a very limited creep under load. Because of this, energy lost from thermal bridging is vastly reduced. Heat flow, energy consumption and potential condensation issues are all greatly reduced.

Armatherm™500 is also available in sheet form. It can be layered easily together to achieve the necessary U value and thickness specifications. Due to its versatility, it can be used anywhere that a penetration is present, or wherever a transition exits through a building envelope, and a thermal bridge occurs. Common examples of these places include: parapets, slab/floor edges, roof penetrations, custom window sills and concrete balconies, along with many others. The material is also user friendly and dynamic; it can be cut and drilled on site easily if required.

Alongside being used to prevent cold bridges and keep temperatures warm within a building, this can also be vital in cold storage facilities to prevent the subgrade from freezing. Plus, it may sit directly under the column base to prevent any transfer of temperature into the ground.

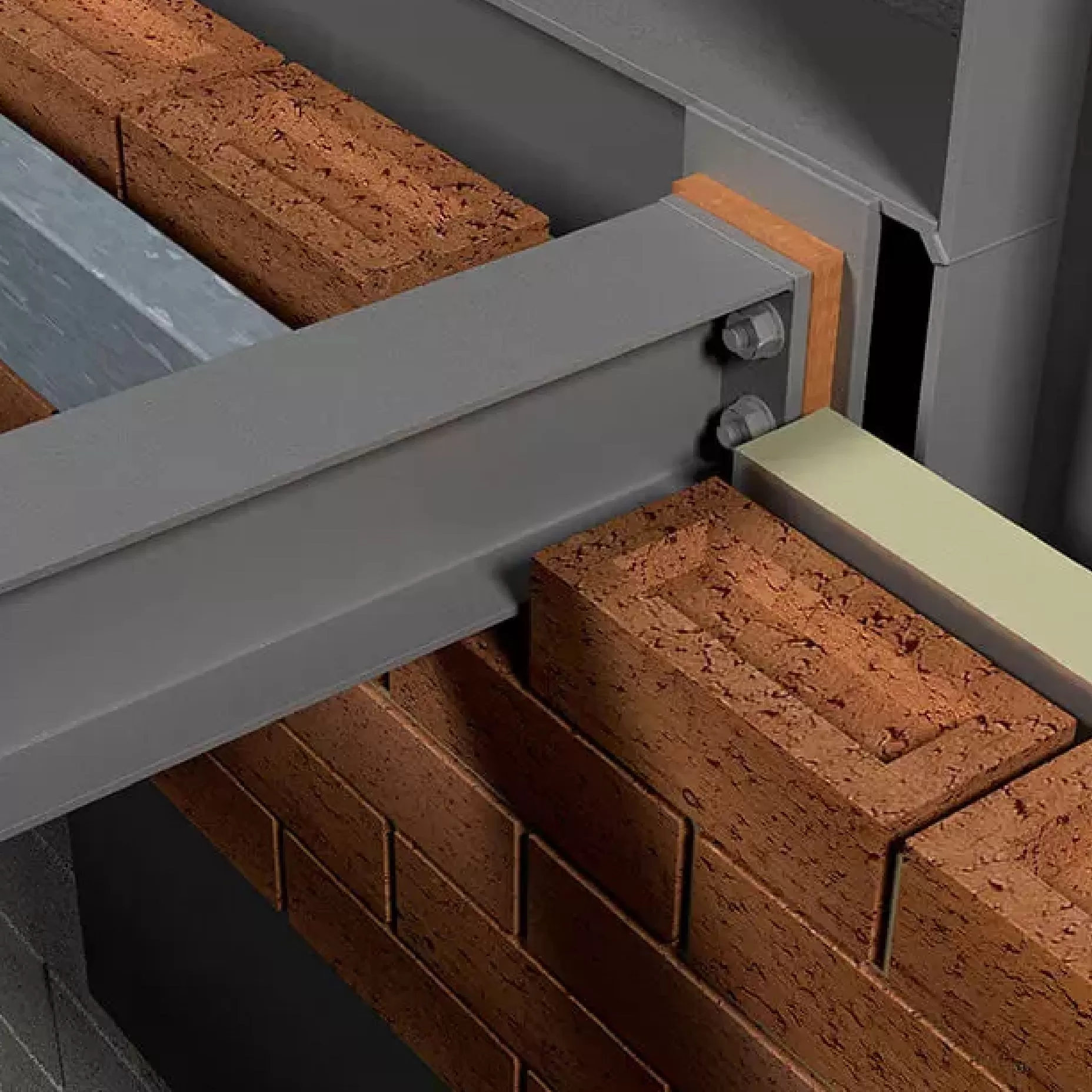

The ArmaGirt™ Z Girt, a non-metallic thermal break, is the perfect solution for new or existing masonry or steel stud backings, as well as within exterior wall projects. Developed to reduce heat loss in the building envelope, Z-girts increase the effective R-value of the total wall assembly. Z-girts are made from fiber-reinforced plastic and tests reveal that incorporating them can result in multiple improvements within the thermal efficiency of the wall design. This includes reducing the heat flow and energy transfers.

The structural material, which is used for holding insulation and mounting cladding, features a traditional Z girt shape and is much more efficient than its steel counterparts. In fact, it offers as much as a 75% improvement over traditional steel Z-girts. This non-conductive solution is invaluable for professionals seeking energy efficient solutions.

Up to 98% efficiency can be achieved through featuring Armatherm™ thermal break products in wall assemblies. Furthermore, they have less potential to develop condensation and damp issues which can be significantly damaging to a building, and the health of those inside. When a combination of thermal break products are specified, cladding attachments are extremely improved. Z-girt, clips and shims are all used to maximise efficiency across the board.

About Armatherm

Our goal at Armatherm™ is to provide architects, structural engineers and building design professionals with the effective requirements to prevent cold bridging. Cold bridging, or thermal bridging, has been recognised as a huge factor in building envelope heat loss. The thermal break materials we provide have low thermal conductivity as well as high strength. They have been designed and tested specifically to prevent thermal bridging.

Armatherm™ thermal bridging solutions can be used wherever a transition exists in a building envelope creating a thermal bridge, to provide continuous insulation. Armatherm™ is an innovative solution with structural thermal break materials to minimise heat loss at balcony, canopy, parapet, masonry shelf angle and cladding connections. Thermal insulation materials must be considered by specifiers, architects and structural engineers to ensure projects are as energy efficient as possible. Therefore saving money in energy costs and protecting the future of constructions.

Request a quote

If you require a quotation and know the following product information, complete through form below.