Applications

ArmaGirt™ Z Girt

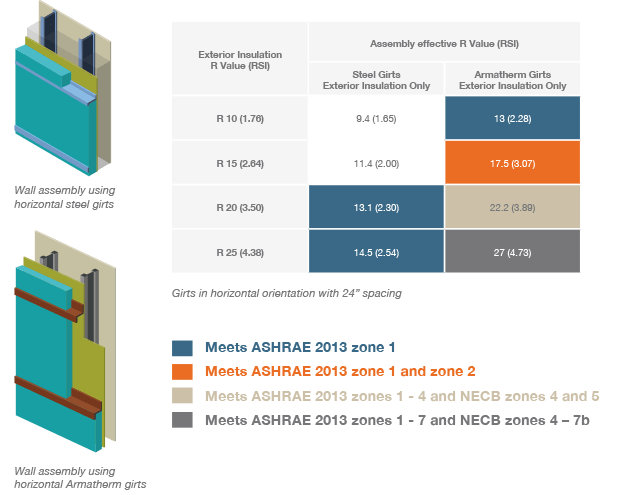

Armatherm thermally broken cladding support connection solutions prevent excessive heat flow and potential condensation problems otherwise associated with thermal bridging. Moreover, wall assemblies using Armatherm attachments will meet the continuous insulation requirement of ASHRAE 90.1 and the effective R value requirements of the Canadian NECB energy code.

Modelling results show that using ArmaGirt™ Z girts results in several improvements in the thermal efficiency of wall designs, reducing heat flow:

- The insulation efficiencies of the wall assemblies increase significantly. Some as high as 98%.

- Higher, effective wall assembly R values are achieved using lower values of external insulation. For example, to obtain an R value of R-13 minimum to meet ASHRAE zone 1, steel girts require and external R 20; whereas Armatherm girts require only R 10.

- Cladding wall assemblies can meet the R value requirements of ALL geographical zones for both ASHRAE 2013 and NECB 2011 energy codes using ArmaGirt™ Z girts.

- Reduction in thickness and cost of insulation.

- Reduces energy consumption.

OurAccreditations

Improve Wall Assembly Efficiency

How can we improve cladding attachment details and design wall assemblies that maximise insulation values so they reduce heat loss, reduce cost and meet energy codes?

Armatherm cladding attachments significantly improve wall assembly thermal performance. ArmaGirt™ Z Girt, clip and thermal break shims provide a combination of low thermal conductivity and high mechanical properties that transfer load and reducing heat loss.

Armatherm resources

Downloads

Request a Quote

If you require a quotation and know the following product information, complete through form below.

When it comes to projects that include cladding and panels, these are more often than not attached to the steel stud framing with a metallic Z Girt. The metal designs are highly conductive, and they can bypass the exterior insulation making it non continuous, resulting in thermal bridges. A thermal bridge, also known as a cold bridge, heat bridge, or thermal bypass, is an area which has higher thermal conductivity than the surrounding materials, creating a pathway for energy transfer. Thermal bridges at the steel girts connection are often overlooked when calculating a wall assembly’s true working U-value. Steel z girts, designed to carry exterior insulation, are very conductive, and because they are attached to the steel stud-wall, are a thermal bridge themselves! The unaccounted heat flow can cool the internal side of steel and aluminum attachments below the dewpoint of air in the wall cavity where condensation can occur, which can cause major issues during the building’s lifespan. Condensation can cause damp patches which can result in dangerous mold problems which can negatively affect a resident or visitor’s health. ArmaGirt™, pultruded fiberglass Z Girts, are non conductive and provide a secure surface to attach siding or cladding.

An ArmaGirt™ Z Girt system is strong enough to hold most cladding and insulation details, and can improve the U value of cladding and wall panel assemblies by eliminating the use of a highly conductive metal girt and aluminum brackets creating wall assemblies that are up to 98% efficient. The addition of a fiberglass Z Girt, made from reinforced plastic, improves the U value of cladding and wall panel assemblies by eliminating the use of highly conductive metal girts and aluminum brackets, creating wall assemblies that are up to 98% efficient. It’s imperative that specifiers, architects and structural engineers are up to speed with the latest in thermal break technology to ensure their buildings are made as efficiently as possible to protect the future of construction. ArmaGirt™ Z Girts come in 7 standard sizes, 1.5”, 2”, 2.5”, 3”, 3.5”, 4”, 6”, which will satisfy most insulation requirements. Our customers have been very satisfied with the quality and consistency of our Z Girts, and the quick quoting and fast delivery.

We’ve provided thermally broken Z Girts for a number of prestigious projects to improve building efficiency. If you’d like to hear from any of the companies we’ve worked with, check out the testimonials on our website which include a number of constructions that feature fiberglass z-girts. We have glowing reviews and our team would be more than happy to put your mind at ease regarding any questions you may have regarding horizontal Z Girts.

ArmaGirt™ Z girts thermal bridging solutions are always safe, durable and efficient. Our thermal bridging solutions are also imperative to help minimise energy loss and, therefore, will significantly improve envelope performance. This is especially true when they are paired alongside Armatherm™’s vast range of thermal break products. Our products are also specifically designed to combat new building regulations. Our expert team is on hand to help and advise when you’re choosing the best product for you and your construction, this includes specialist knowledge on fiberglass Z Girts. For helpful online resources, including test reports, design assistance, literature libraries and ZGirt product profile videos, visit our website. They can help you gain a better understanding of thermal break products, key features and best suited applications.