Armatherm application

Product

Masonry Shelf Angle

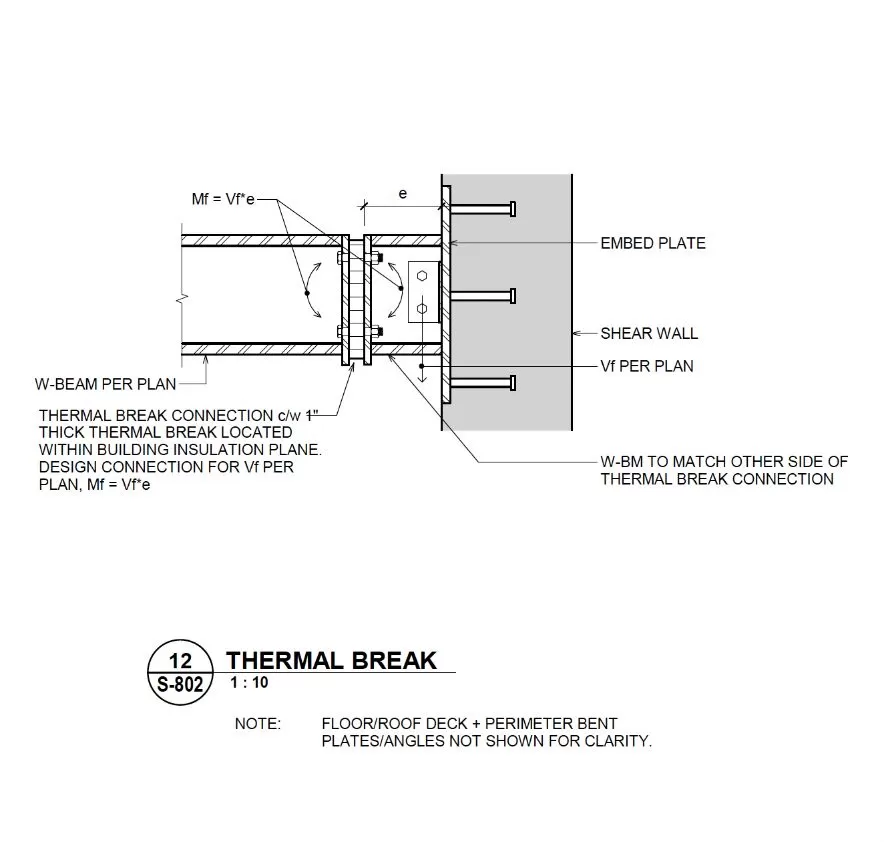

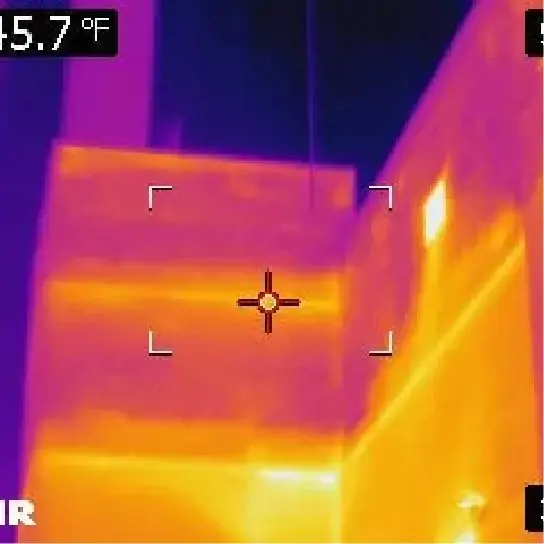

Masonry veneer walls require tie-backs and shelf angles which form significan’t thermal bridges and can reduce a walls’ R value by as much as 50% making it difficult to meet energy codes. Shelf angles transfer the masonry load back to the buildings’ structural steel or concrete slab edge interrupting the continuous insulation of the wall assembly creating a linear thermal bridge.

To improve the U value of a masonry wall assembly, the shelf angle can be connected to the structure at discreet, evenly spaced points such as plate “blades” allowing the insulation to pass behind the steel angle, thus reducing the effects of a continuous thermal bridge. However, building the shelf angle outwards requires larger geometries and additional material to support the cantilevered load.

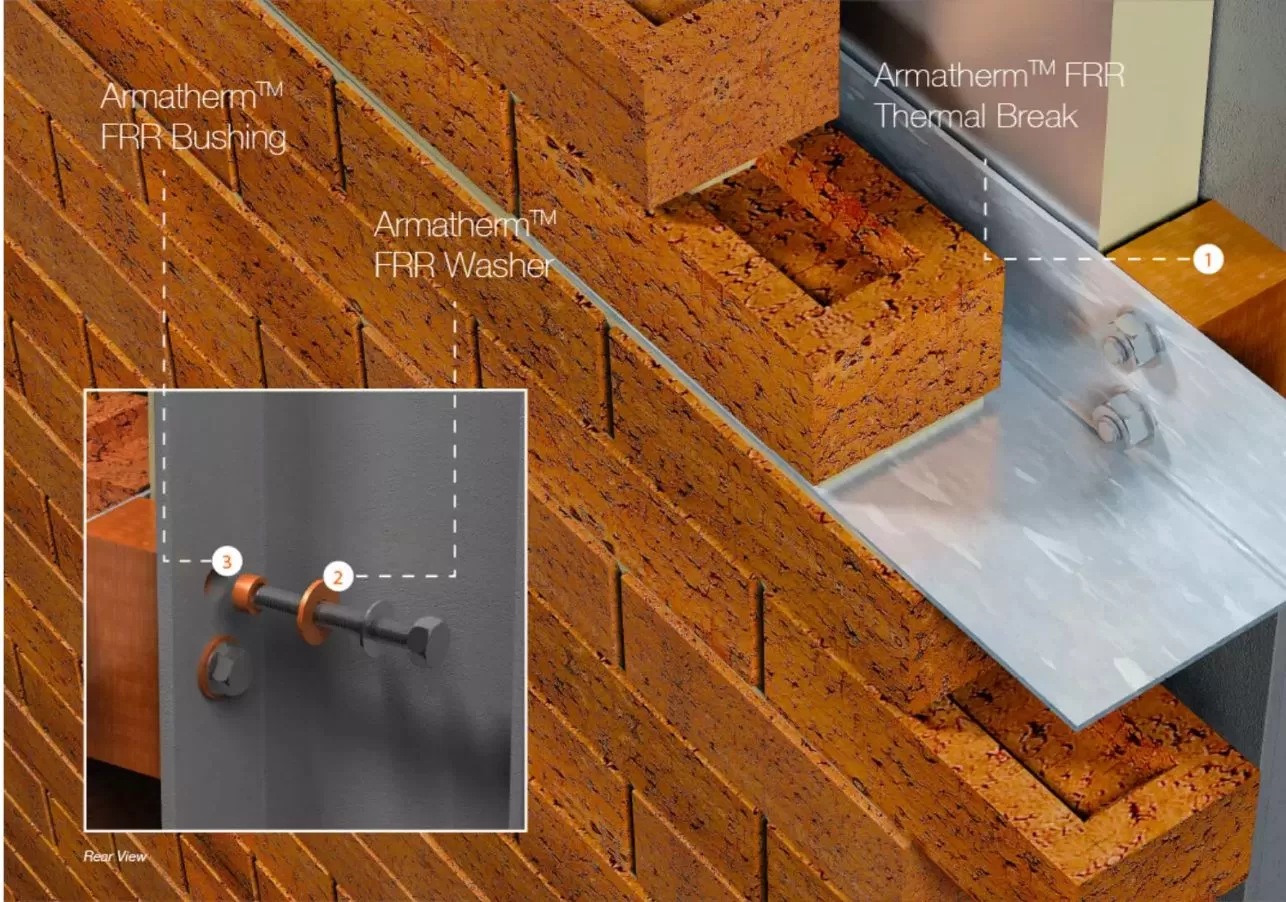

ARMATHERM™FRR Benefits

- Only needs to be at bolt through connection points

- Pad depth matches angle height

- Pad width to suit load

- Recommended thickness two inch

- Pads cut and drilled for ease of installation

- Lasts the life of the building

Improving Wall Assembly Efficiency

Alternatively, Armatherm™ FRR structural thermal break material can be used directly behind the masonry shelf angle as a thermal break within the insulating layer. The Armatherm™ thermal break significantly reduces the linear transmittance (heat loss) of the shelf angle connection. Rigid, metal flashing used as waterproofing can also be replaced with a non-conductive, self-adhered membrane to reduce the effects of thermal bridging further.

Armatherm™ Masonry Shelf Angle

Downloads

Request a Quote

If you require a quotation and know the following product information, complete through form below.